MCSBR

MCSBR (Modified-CSBR, NET Certification No.585 Verification No. 285, Patent No.10-2361659)

Expand the treatment capacity plant that has reached its treatment limit by up to 150%

with the MCSBR unit process using the existing method.

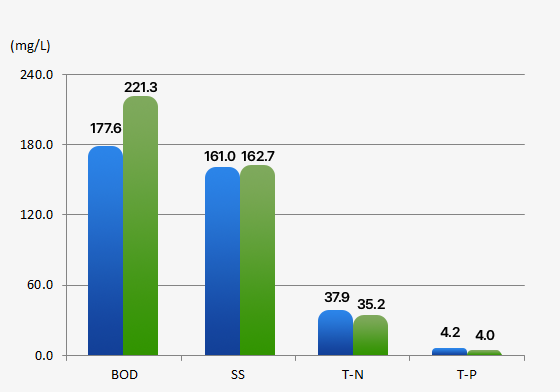

<NET Process Diagram>

* Net name : Advanced biological sewage treatment technology combining functional media and cyclone

* Net name : Advanced biological sewage treatment technology combining functional media and cyclone

Features

To strengthen sludge settling and improve treatment efficiency :

-

Aerobic tank improvement > Introducing functional media for the growth of attached microorganisms

-

Sludge return line improvement > Application of hydrocyclone to sludge return system for improved sludge settling characteristics and denitrification ability

-

Non-stop operation of existing treatment facility > Facility enhancement within 6 months of construction period without structural changes and without treatment interruption

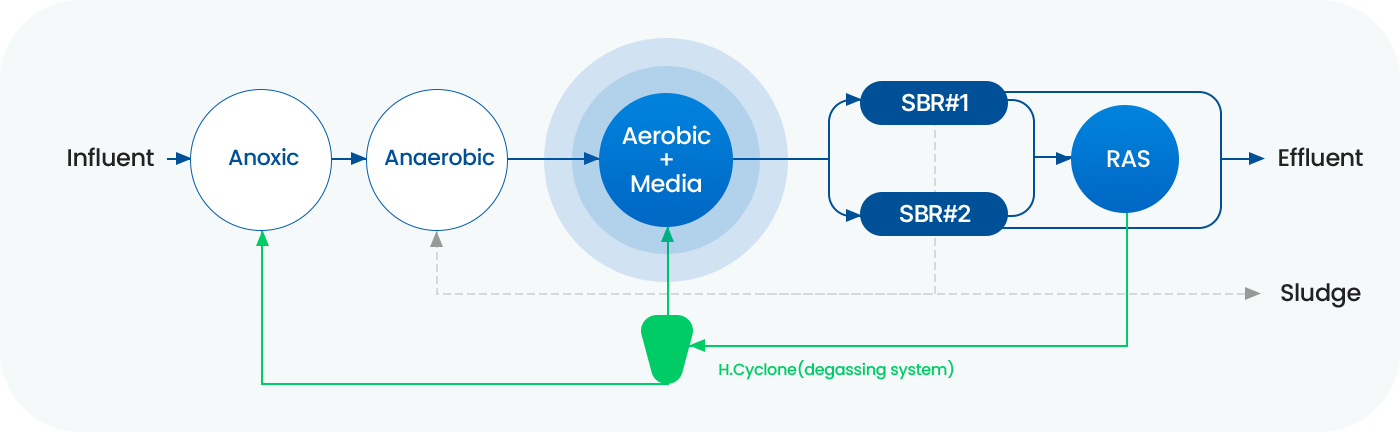

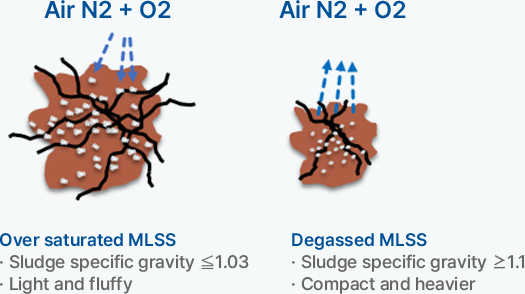

Hydrocyclone (Degassing system) Principle (Patent No.10-2361659)

The oversaturated nitrogen and oxygen in the sludge during the aeration process is removed with the hydrocyclone due to the pump head pressure difference . The sludge is effectively desorbed and circulated back into the reactor, improving the denitrification and phosphorus removal mechanisms and improving sludge concentration and sedimentation performance, enabling more than 30% increase in treatment capacity.

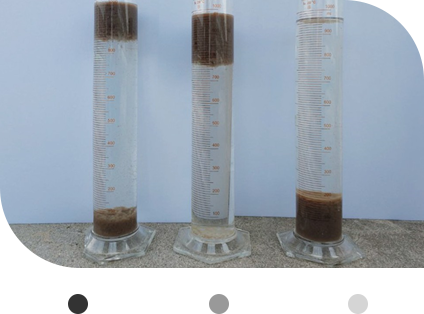

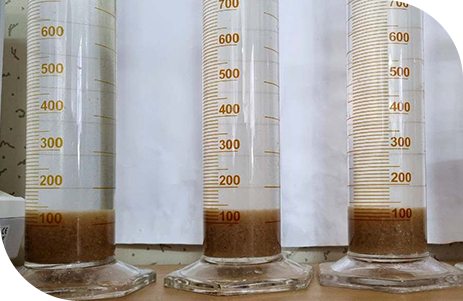

Activated Sludge Decompression / Degassing Sedimentation Test Results

Proof that only sludge degassed under reduced pressure maintains a stable interface.

Natural sedimentation

Sedimentation after areation

Sedimentation afrter decompression

Case Study of Samsung Electronics’ Pyeongtaek Godeok Industrial Complex Semiconductor Wastewater Treatment Facility (Phase

1):

Expansion of existing facility capacity from 102,000 tons/day to 120,000 tons/day using MCSBR Process

Client Requirements

It was necessary to expand the existing Wastewater Treatment plant due to the expansion of the Pyeongtaek Semiconductor

Factory following the withdrawal of China/Vietnam.

However the site of the existing Wastewater Treatment Plant was too small, so relocation/new construction would delay the

main factory plan up to 5 years.

> After a six-month global technology survey conducted by Samsung Electronics, Rothwell Water's NET excellent environmental

technology was Selected as the optimal solution.

Facility Conditions:

① No Change of existing structure

② No Discontinuation of treatment plant operations

③ Expansion constructioncompleted within 6 months

④ Mandatory start up: 6 months

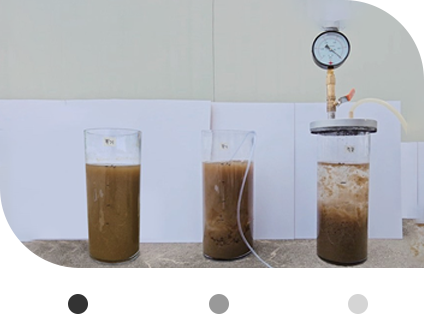

Applied Photos Hydrocyclone10m3/min×6ea installed (2ea per train)

Application results

MCSBR technology was applied to the above ground area of the Wastewater Treatment Plant to meet the facility conditions.

The over all construction cost was 20% compared to the cost of a new installation;

treated water quality values were below the design standards;

and a treatment capacity increase of 120% or more was perfectly achieved in a period of 6 months of construction

and 6 months of performance guarantee test run.

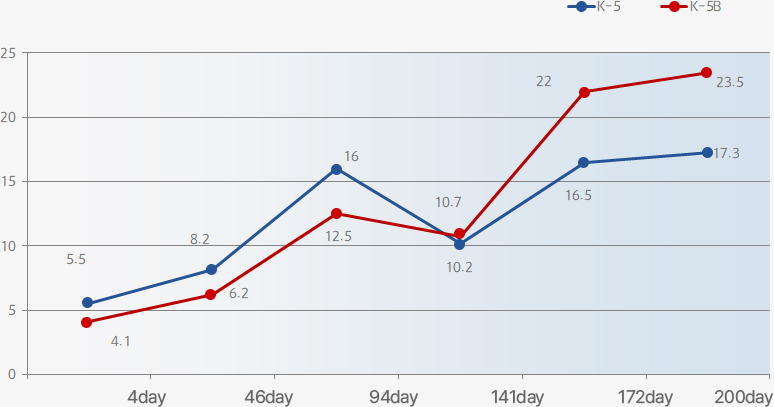

[SV30 measurement results before and after applying the MCSBR process] Significantly improved sludge settling and sludge condition

SV30 Before application Aerobic tank series 1,2, and 3, December 2021

SV30 After application Aerobic tank series 1,2, and 3, Jenuary 2022

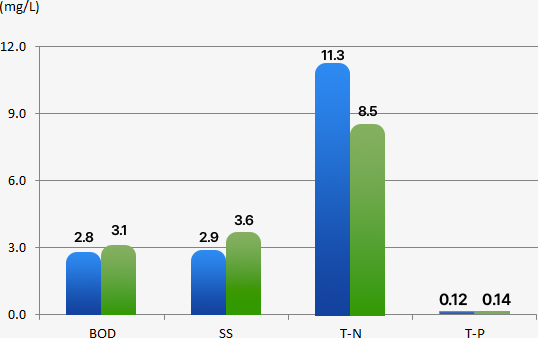

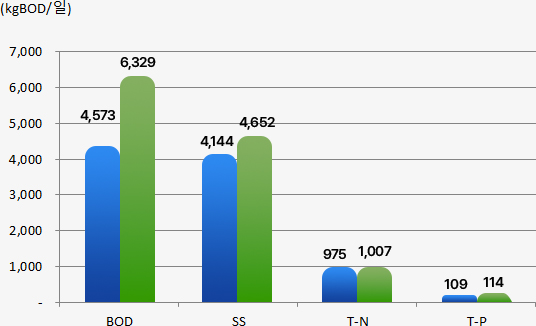

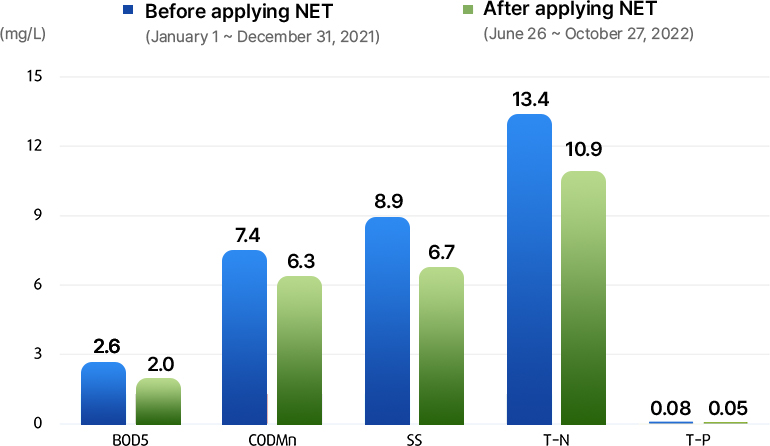

Changes in Water quality of bioreactor after applying NET

Even though wastewater inflow increased by 33%, the quality of the bioreactor treated water improved by more than 20%

on average after applying MSCBR new technology.

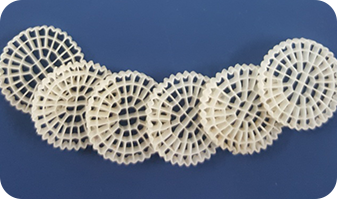

K-5B Functional Media with Enhanced Microbial Adhesion (Patent No. 10-1927520)

Korean design patent K-5 Media (“Microbial House”) has lately been adopted for MBBR Process of Veolia Water. Similarly, Rothwell has succeeded in developing the world's best functional media K-5B having 30% more adhesion capacity for microbes than K-5 by blending the trehalose substance, which is in the spotlight as a moisturizer in cosmetic’s industry, into the media using a special blending know-how.

Media manufacturing process

-

01

Mystery of vitality 'Jericho',

the rose in the deser -

02

Injection Molding Machiner

-

03

Trehalose Nutrient powder +

Raw HDPE -

04

K-5B Media

Authentication / Verification Performance

Once microbial attachment is completed, K5-B boasts more than 30% adhesion capacity compared to K-5.

K - 5B

K - 5

Case study of Goyang City Byeokje Sewage

Treatment Plant : Expansion from 30,000 tons/day

to 31,200 tons/day

Comparison of design operating conditions before and after application

of NET / MCSBR

Reason for applying new NET: Increased inflow load at treatment plant

| Item | Unit | Before applying NET (Existing facility) | After applying NET | ||

|---|---|---|---|---|---|

| Influent water quality |

Effluent guaranteed

water quality |

Influent water quality |

Effluent guaranteed water quality |

||

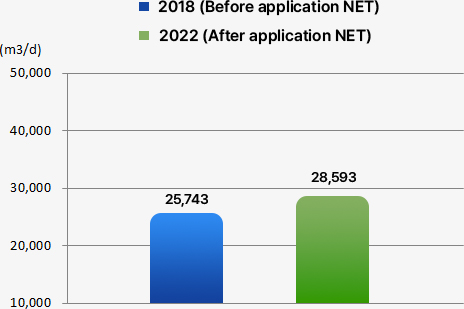

| Flow rate | m3/d | 30,000 | 31,200 | ||

| Temperature | ℃ | 15 | 12 | ||

| BOD | mg/L | 125.0 | 10.0 | 211.0 | 5.0 |

| CODMn | 118.0 | 15.0 | 189.9 | 15.0 | |

| SS | 118.0 | 10.0 | 225.3 | 5.0 | |

| T-N | 26.4 | 15.0 | 46.1 | 15.0 | |

| T-P | 4.6 | 2.0 | 7.3 | 0.3 | |

Results of MCSBR application

Comparison of operation results before and after MCSBR application